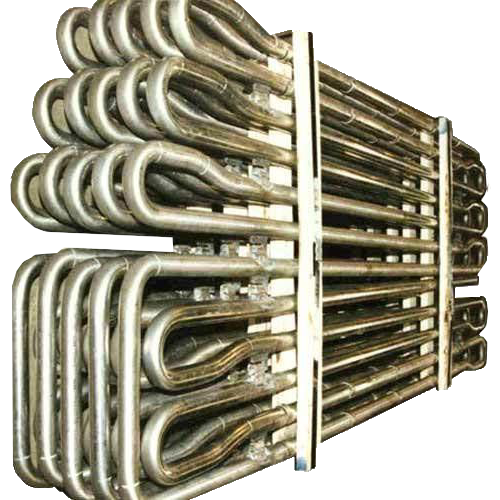

We manufacture Super heater coils in various

grades of Alloy steel T1, T9, T11, T22, T9 &

T91, BS: 3059 320/360 PT l/llnd in stain less

steel tubes SS 304, SS310, SS316 and SS 347H

with or without support & Header as per

customer’s drawing and specifications. as per

I.B.R. 1950. A super heater is a crucial component in a boiler system designed to increase the temperature of saturated steam to achieve higher energy efficiency and performance.Super heaters are typically installed in the convective or radiant heat transfer zones of the boiler, downstream of the primary heating surfaces such as the combustion chamber, furnace, and boiler tubes.