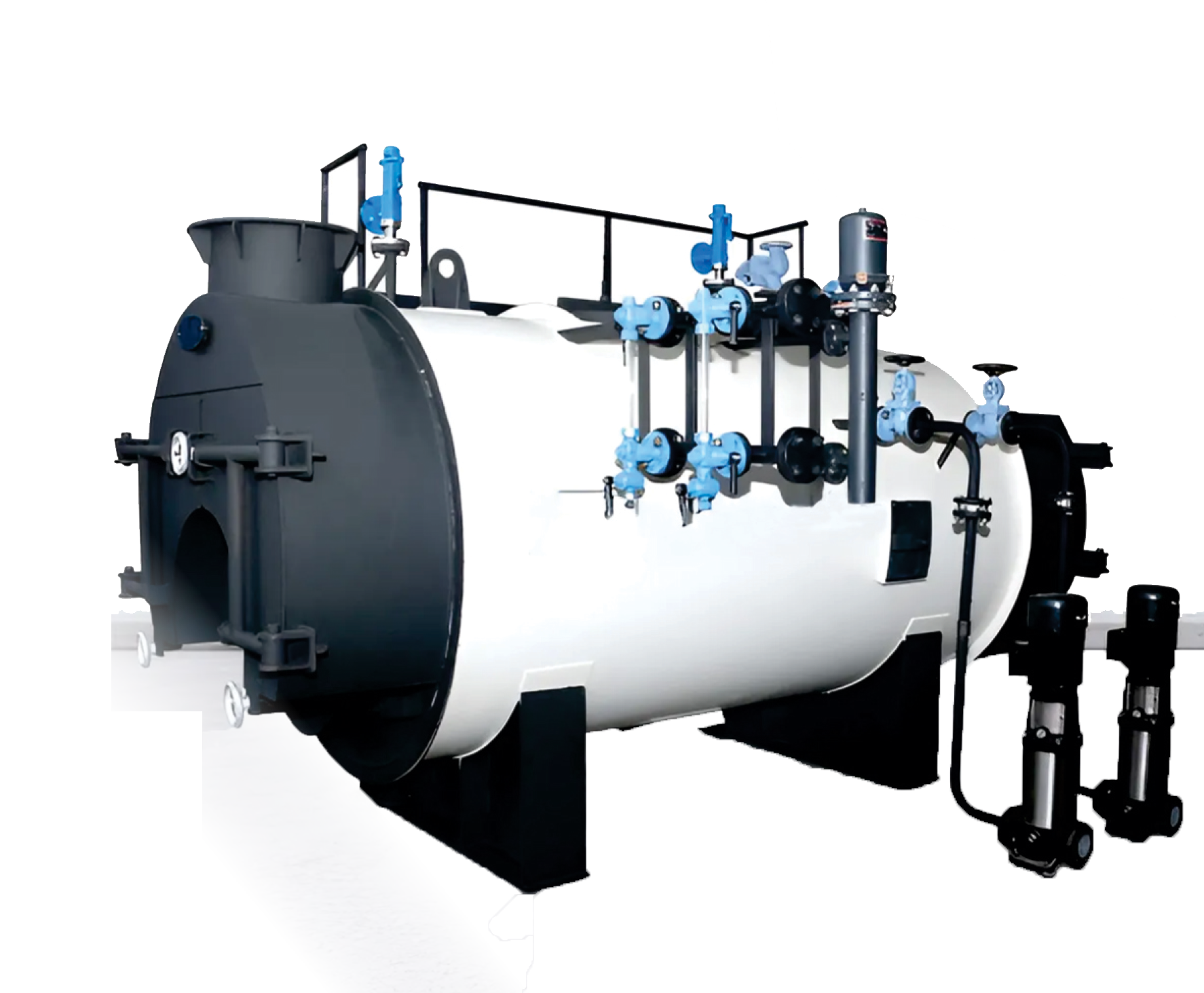

We're committed to providing eco-friendly boiler solutions that minimize environmental impact.

Our team of engineers and technicians are among the best in the business, bringing & passion for innovation.

We go above and beyond to exceed your expectations, providing prompt, reliable service and support every way.

We believe in a hands-on approach that begins with understanding your unique needs and challenges.

We meticulously select our raw materials from reputable suppliers known for their commitment to quality and reliability to ensure it meets our exacting standards.

we are dedicated to delivering world-class engineering and design solutions that set the standard for excellence in the industry. Trust us for innovative, solutions

With our 24/7 service support, you can have peace of mind knowing that help is always just a phone call away. Whether it's the middle of the night, a holiday, or a weekend, we're here to support you.

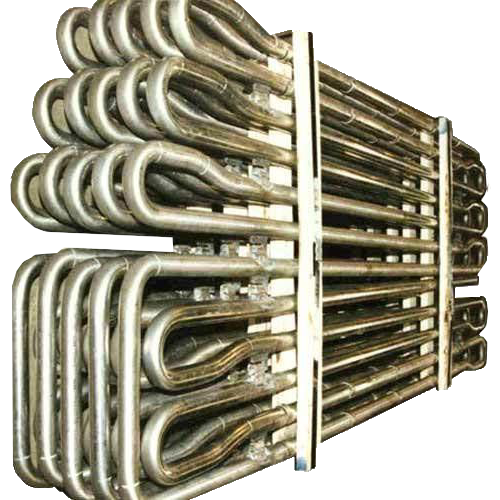

A CNC (Computer Numerical Control) Tube Bending Machine is a sophisticated piece of equipment designed to automate the tube bending process with high precision and efficiency. These machines are integral to various industries, enabling the production of complex tube shapes and bends that meet stringent specifications and quality standards.

A welding machine, also known as a welder or welding power supply, is a piece of equipment used to join materials together by creating a strong bond at the molecular level. These machines use an electric arc to generate heat, melting the base materials and filler metal to form a weld joint.

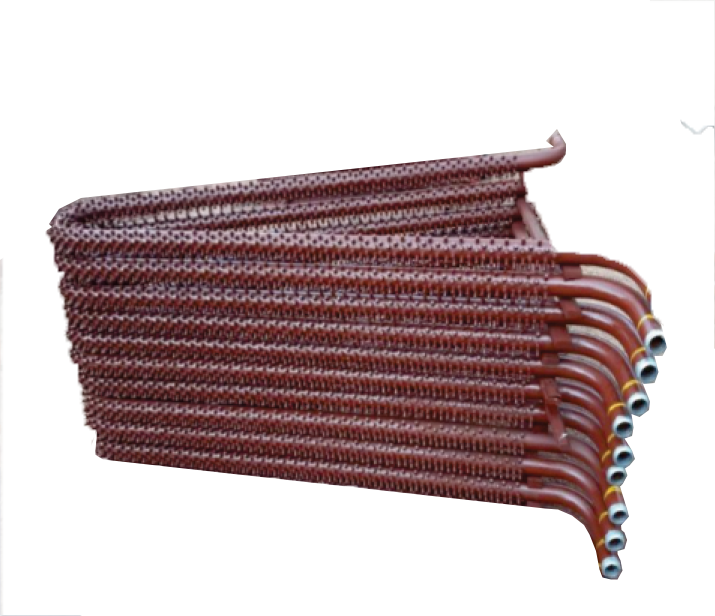

A Venturi type wet scrubber is an air pollution control device that uses liquid, typically water, to remove particulate matter and gaseous pollutants from industrial exhaust streams. This type of scrubber is highly effective in capturing fine particles and gaseous contaminants, making it a crucial component in industries such as power generation, chemical manufacturing, and metal processing.

Connect with us for your boiler solutions and We’re ready to discuss your boiler needs.

Punjab

Uttar Pradesh

Madhya Pradesh

Gujarat

Bihar

Jharkhand

Odisha

Maharashtra

Punjab

Uttar Pradesh

Madhya Pradesh

Gujarat

Bihar

Jharkhand

Odisha

Maharashtra

Khasra No-615, Jansath Road, Nairana Muzaffar Nagar- 251203 ( U.P.)

Copyright 2024 Reserved By western Boilers | Website Design With ❤️ By Grain e media