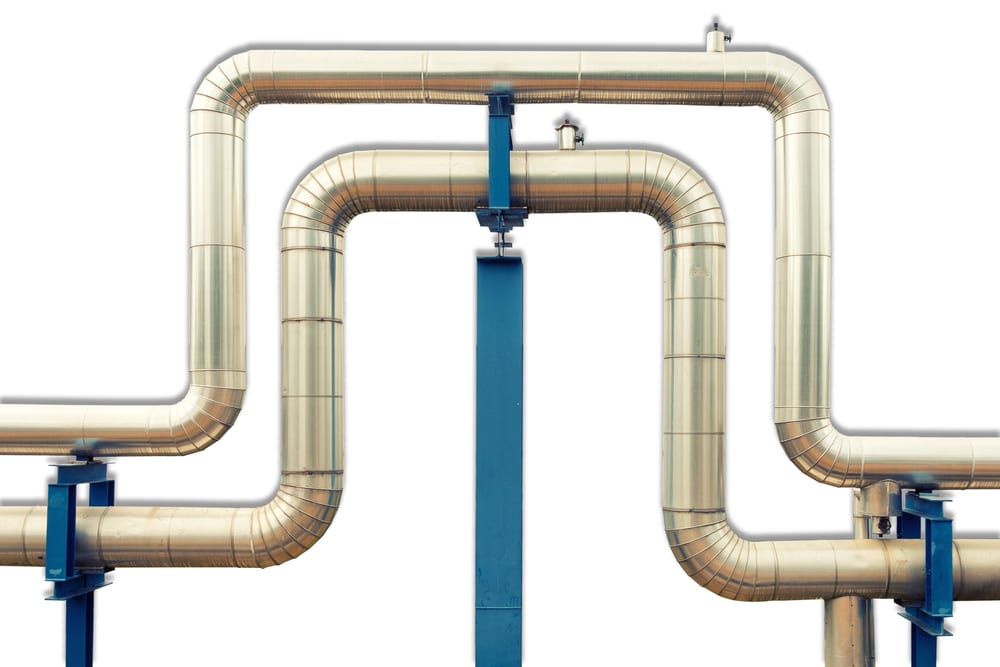

We are supply fabrication & Erection

steam pipe line as per I.B.R. 1950. Steam pipeline systems form the lifeline of industrial operations, transporting high-pressure steam from boilers to various points of use throughout a facility. These systems are meticulously designed and engineered to ensure reliable steam delivery, optimal energy transfer, and safe operation.