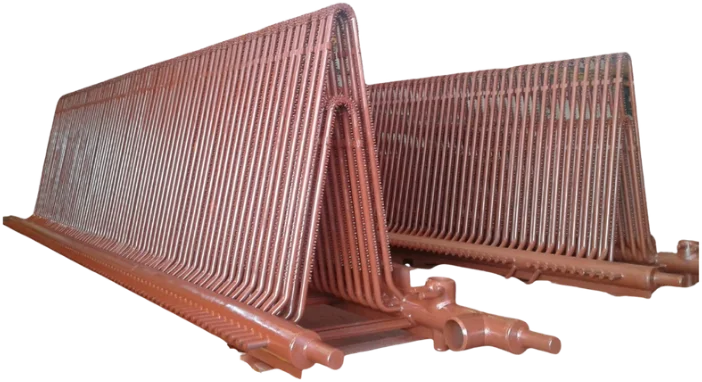

We offer a comprehensive range of studded & plain inner/ outer

bed coils that we manufacture from quality carbon steel or alloy

steel. These coils can be customized as per the specific

requirements of the clients. as per I.B.R. 1950. Bed coils are integral components of boilers designed to enhance heat transfer efficiency and optimize steam generation in industrial processes. These coils are strategically positioned within the boiler’s combustion chamber,