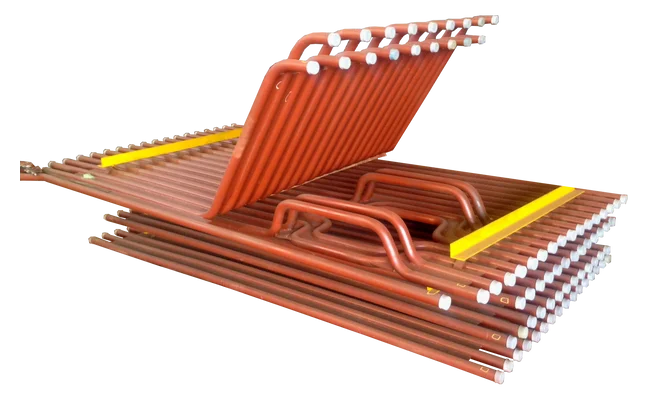

We manufacture Water wall panel & tubes with a without fins with swaged (reduced diameter)

ends are manufactured by us. as per I.B.R. 1950 Material BS: 3059PT/V/l I Seamless/ERW/

SA210 GR-AI Seamless. Water wall panels are key components in water-tube boilers, serving multiple functions including heat absorption, steam generation, and structural support.